In March 2022, we celebrated that the UN Environment Assembly (UNEA) passed a historic resolution to end plastic pollution. Digimarc committed to cross-industry collaboration a few months later, joining the Ellen MacArthur Foundation, World Wildlife Fund (WWF), and 80+ other organizations to support the Business Coalition for a Global Plastics Treaty.

Recently, the UN Environment Programme (UNEP) released an update on progress toward the shared goal of a future where plastics no longer exist as waste or pollution. While many of the updates were expected, several findings highlighted by UNEP caught my eye as we work toward systemic change. Specifically:

Reuse isn’t a new concept, but recently we’ve witnessed major corporate entities and governments embrace reuse options with renewed commitment. For instance, last month, we announced a five-year, $32M+ deal with an international solutions provider that included guarding the integrity of a national deposit-return system (DRS), combining Digimarc’s excellence and expertise in anti-counterfeiting and recycling to support increased circularity of food and beverage containers. We hope other governments will act with the same urgency in building a solid business case for reusables.

On the recycling front, UNEP states the opportunity most clearly in reference to technology innovation.

Important to highlight: the innovative technology to effect change exists today! In Europe, the HolyGrail 2.0 project announced the results from European trials that showed that digital watermarking technology has the power to transform recycling. The effectiveness of Digimarc Recycle has also been validated in Canada by the Circular Plastics Taskforce (CPT).

The results of these tests are laying the groundwork for the global rollout of this technology. In Canada, the initial focus is on tackling flexible plastics that are poorly recycled, presenting untapped potential. Across the Atlantic, France has been identified as the first European market to advance the adoption of Digimarc Recycle to improve large-scale plastics recycling.

I also want to highlight UNEP’s comment – “This will require an adequate availability of feedstock that can be recycled and that recycled materials can compete on a level playing field with virgin materials.” A recent report by Roland Berger called plastic recyclate – the new gold. According to the report, new sorting technologies, such as digital watermarks, can substantially improve the yield and quality of recyclates. Digimarc Recycle represents a game-changer in addressing this growing global issue -- improving the sortation and recycling of plastic waste, while also revealing never-before-available data that unlocks benefits for people, planet, and profits. You can read more about the Roland Berger report in this blog.

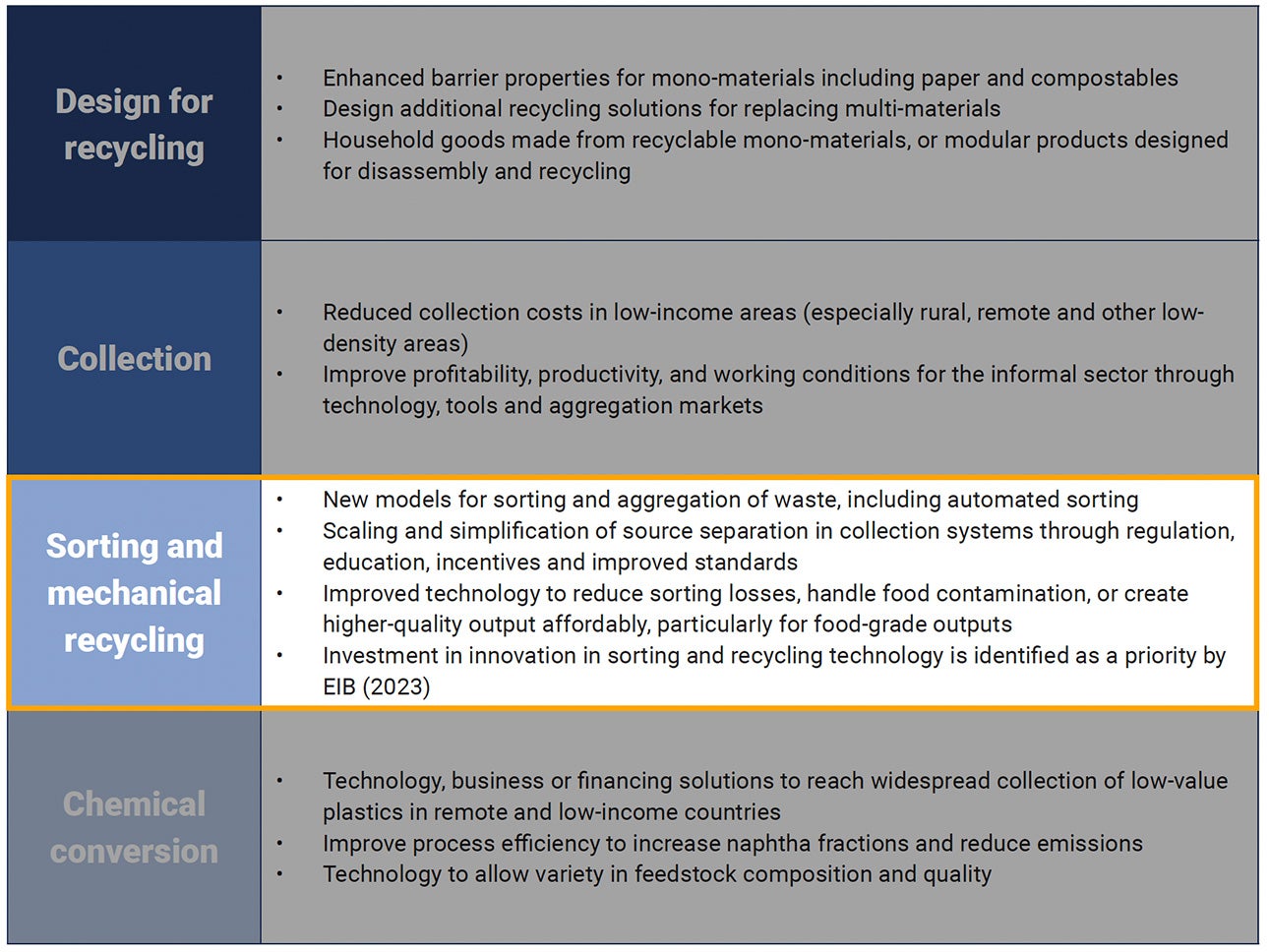

According to UNEP, increasing recyclability depends on local sorting and recycling infrastructure. Companies must select their business models, materials and designs considering the market where the products will be sold. This is especially important for multinational corporations that typically design products and packaging in a central hub for many markets. Harmonized international standards and definitions for design for recycling can make it easier for companies to design products that are recyclable across markets. This is what makes this legally binding UN Treaty so important to get right.

Breaking down the financial impact of adding annual recycling capacity.

Adding extra annual recycling capacity of up to 129 million metric tons by 2040 (instead of letting waste go to landfill) would cost an incremental capital expense (capex) of approximately USD 76 billion net present value (NPV) from 2021 to 2040 and operating expense (opex) of approximately USD 270 billion NPV from 2021 to 2040 (accounting for savings from not building landfill capacity). Offsetting these expenses are the savings of USD 185 billion NPV in capex and USD 290 billion NPV in opex that would otherwise go to virgin plastic production and plastic conversion.

In other words, tripling recycling capacity from the capacity in 2016 (reference page 30 of the UNEP Report) instead of ‘only’ doubling it would create net cost savings overall. The critical condition for this to work is ensuring that this extra amount of plastic waste, which would otherwise go to the landfill, can be designed to be safely mechanically recycled and that the economics of sorting and mechanical recycling is attractive enough to justify these investments. Realizing the fifth United Nations Environment Assembly’s goal to end plastic pollution by 2024 could set the enabling conditions and economic incentives in place to make this a reality – including establishing criteria for transparency and controls on plastics composition.

Alone, these statistics would argue it is economically attractive to be investing in recycling capacity instead of virgin plastic production and conversion. But that doesn’t include the other costs of doing business as usual:

In fact, when direct, environmental and social cost savings are added up, a transformed plastics economy will save more than USD 4.5 trillion, or a 20.3% reduction in costs overall.

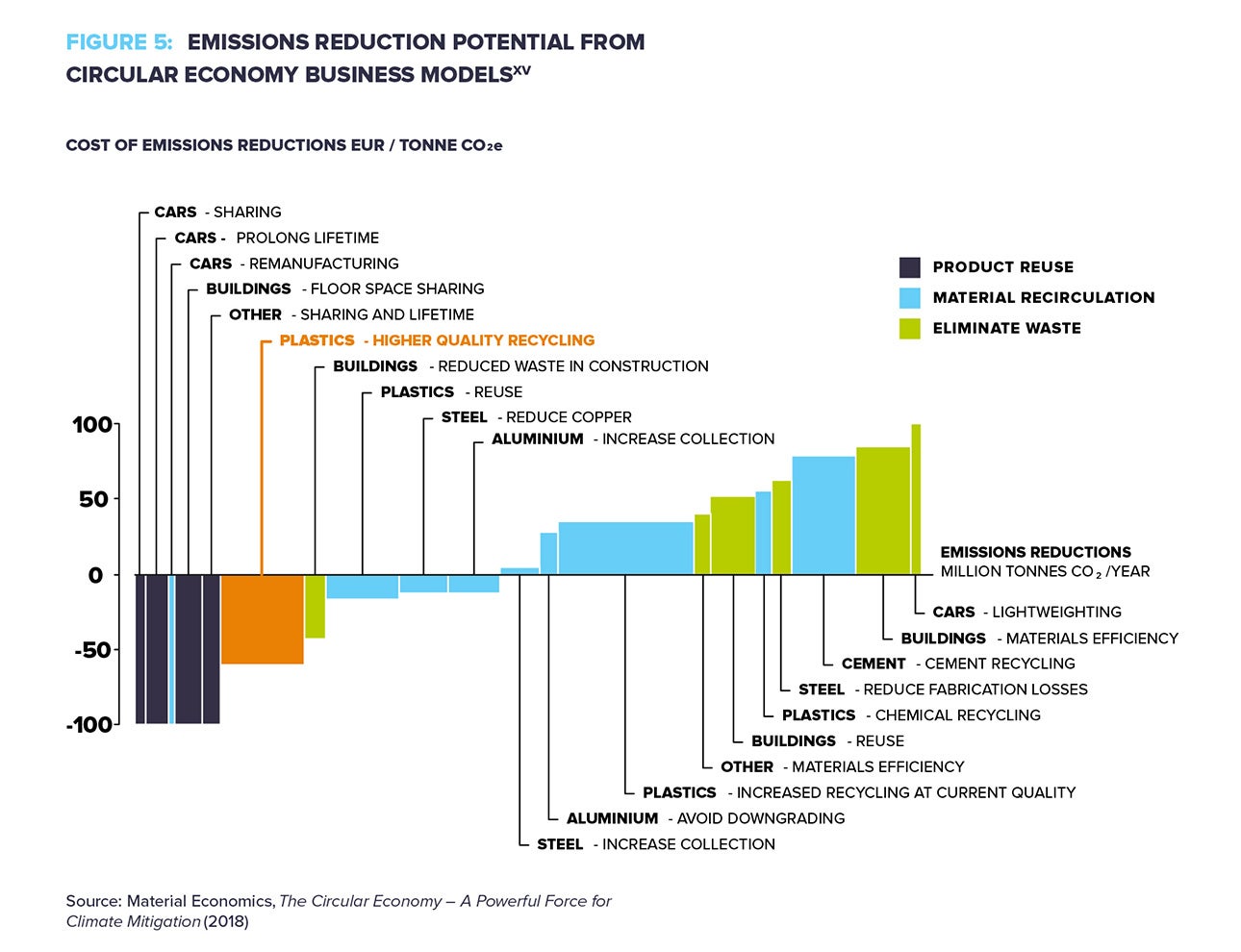

Beyond cost savings through increased recycling capacity, it is also important to note that next-generation recycling isn't just about reducing plastic waste; it is about reducing carbon emissions in a significant and cost-effective way.

According to The Pew Charitable Trusts, under a business-as-usual scenario, plastic could emit 19% of GHG emissions allowed under a 1.5° C scenario by 2040, essentially placing the goal out of reach.

According to the Ellen MacArthur Foundation, higher quality plastics recycling can have a profound impact on reducing carbon emissions and, importantly do it in a “negative cost” – profitable – way.

At Digimarc, we are committed to global collaboration and the shared goal of a future where plastics no longer exist as waste or pollution. We applaud UNEP and all the organizations accelerating this call to action and remain committed to contributing to required systemic change. These organizations recognize that we – all beings on this planet -- have the incredible opportunity to do something that makes sense both economically and environmentally. All that is required is the willingness to overcome inertia and take action.

Global and legally-binding action.

I invite you to connect with me directly here on LinkedIn to continue the conversation.

Riley McCormack is President and CEO of Digimarc.